Service and repairs

While we love to build new bikes we maybe even prefer to keep old bikes riding.

Our extensive knowledge of building bikes in steel and titanium, mastering different techniques and our large (metal)workshop gives us the opportunity to repair, service or adapt existing bikes and frames.

We can TIG weld steel, stainless steel and titanium, filletbraze steel and stainless steel and work with lugs and other classic parts.

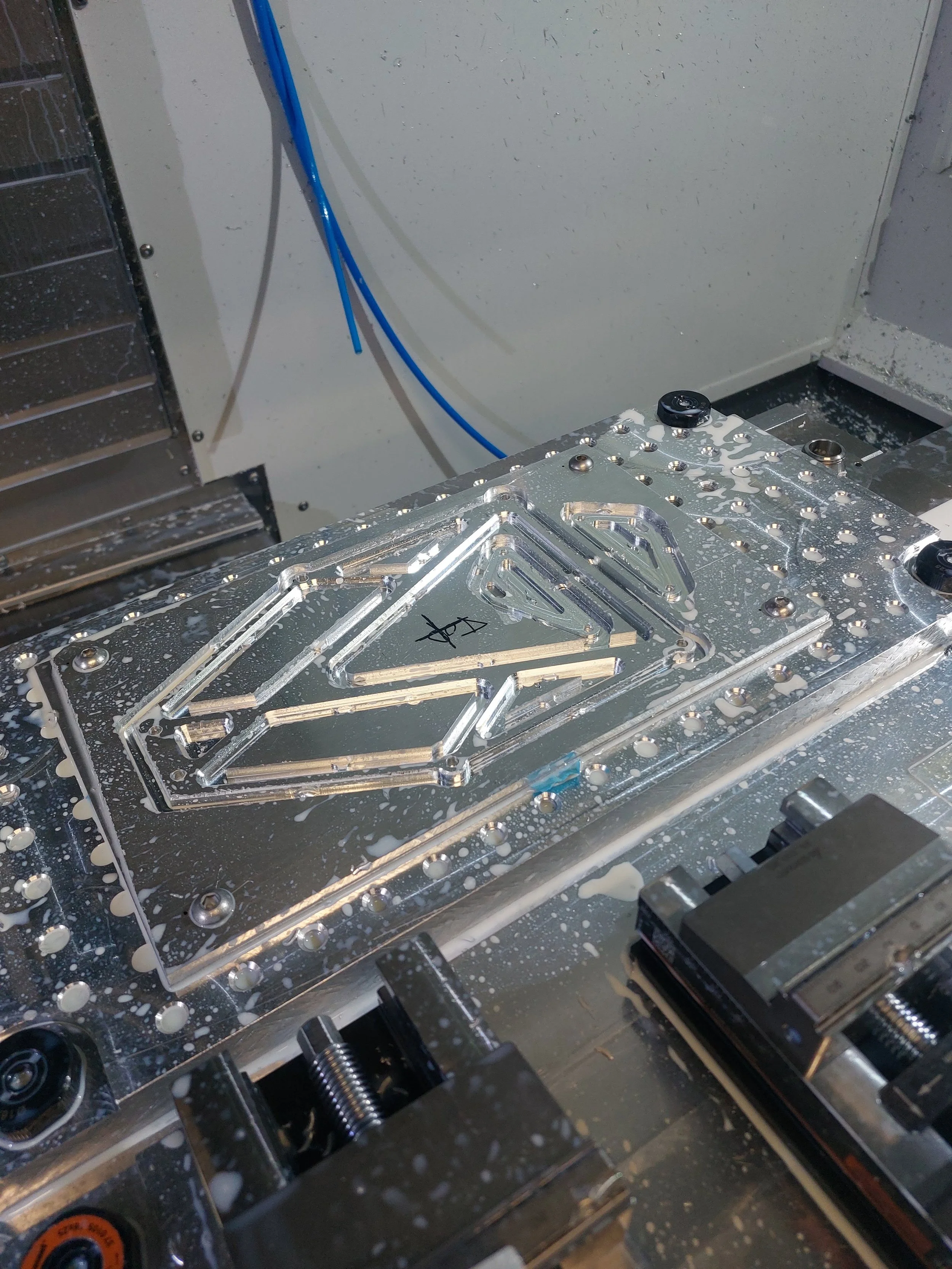

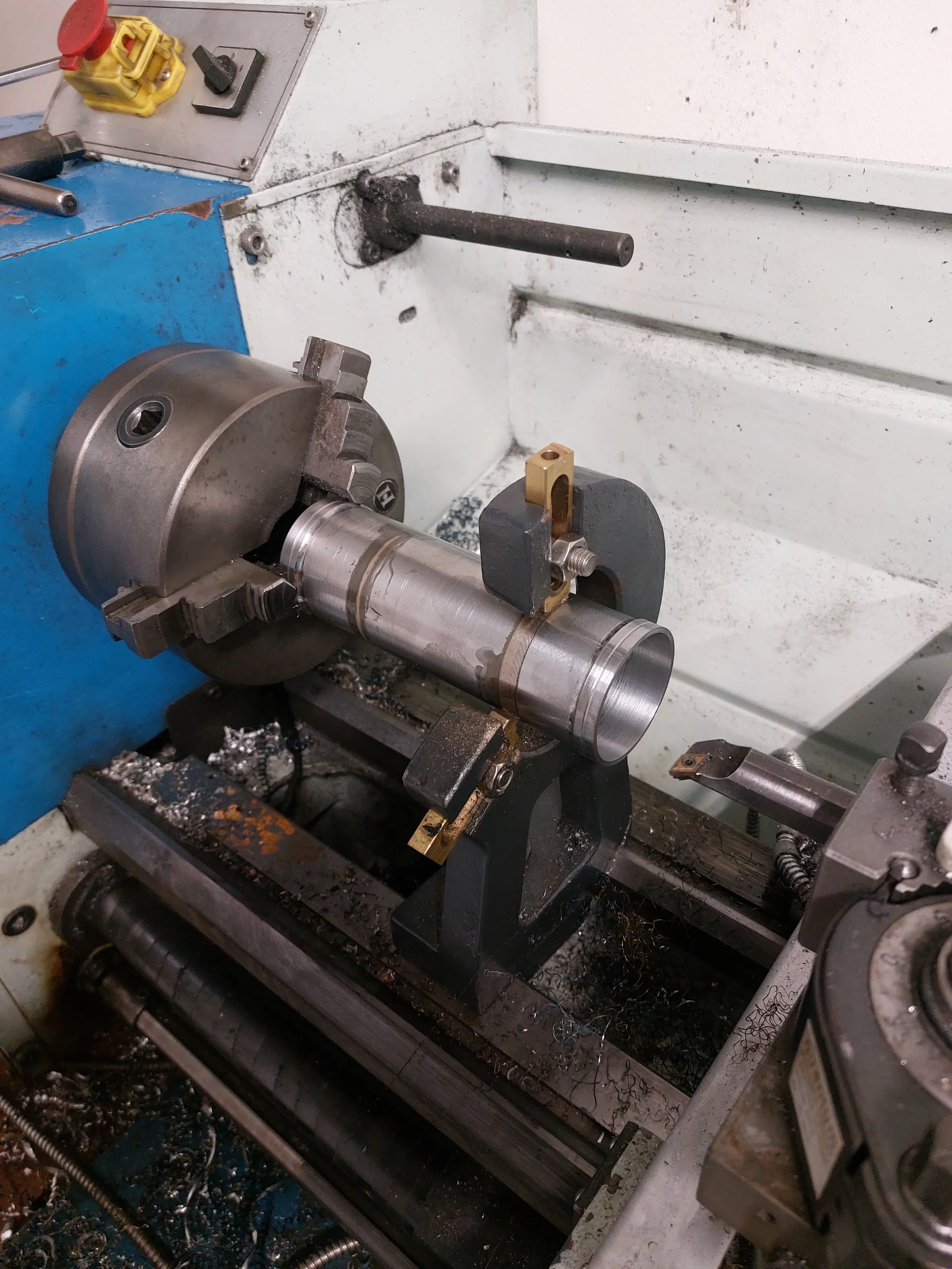

Our metalworkshop with lathes and a Haas CNC machine and several (non metal) 3D printers also makes it possible to fabricate parts.

Fixing a cracked seattube on a fillet brazed steel Vittorio

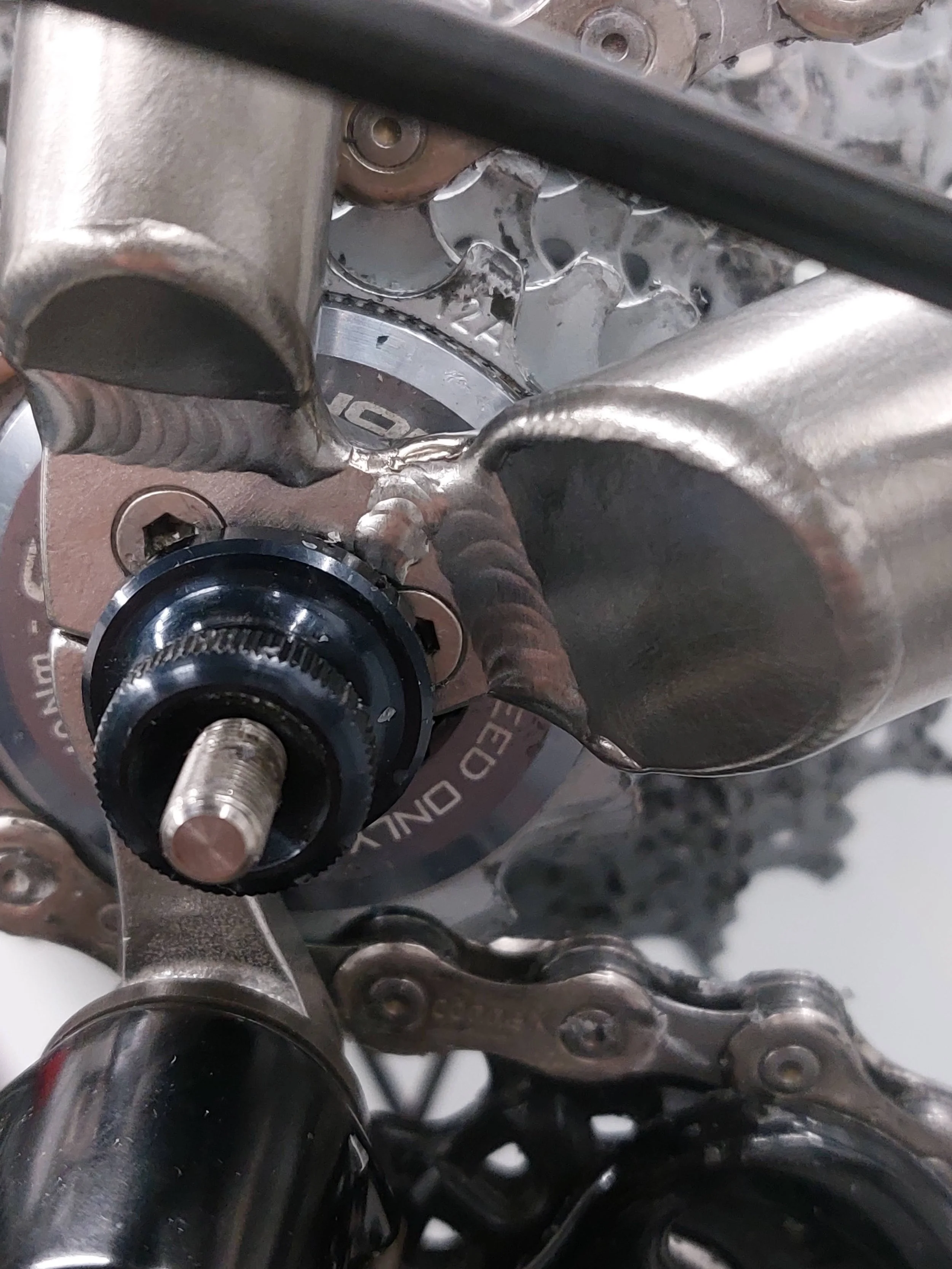

Cracked titanium Litespeed dropout welded. Due to the tiny crack and very thin material quite the challenge!

Replacing a 1” steerer on a classic Vittorio

Machining a custom front rack

Machining custom headtubes

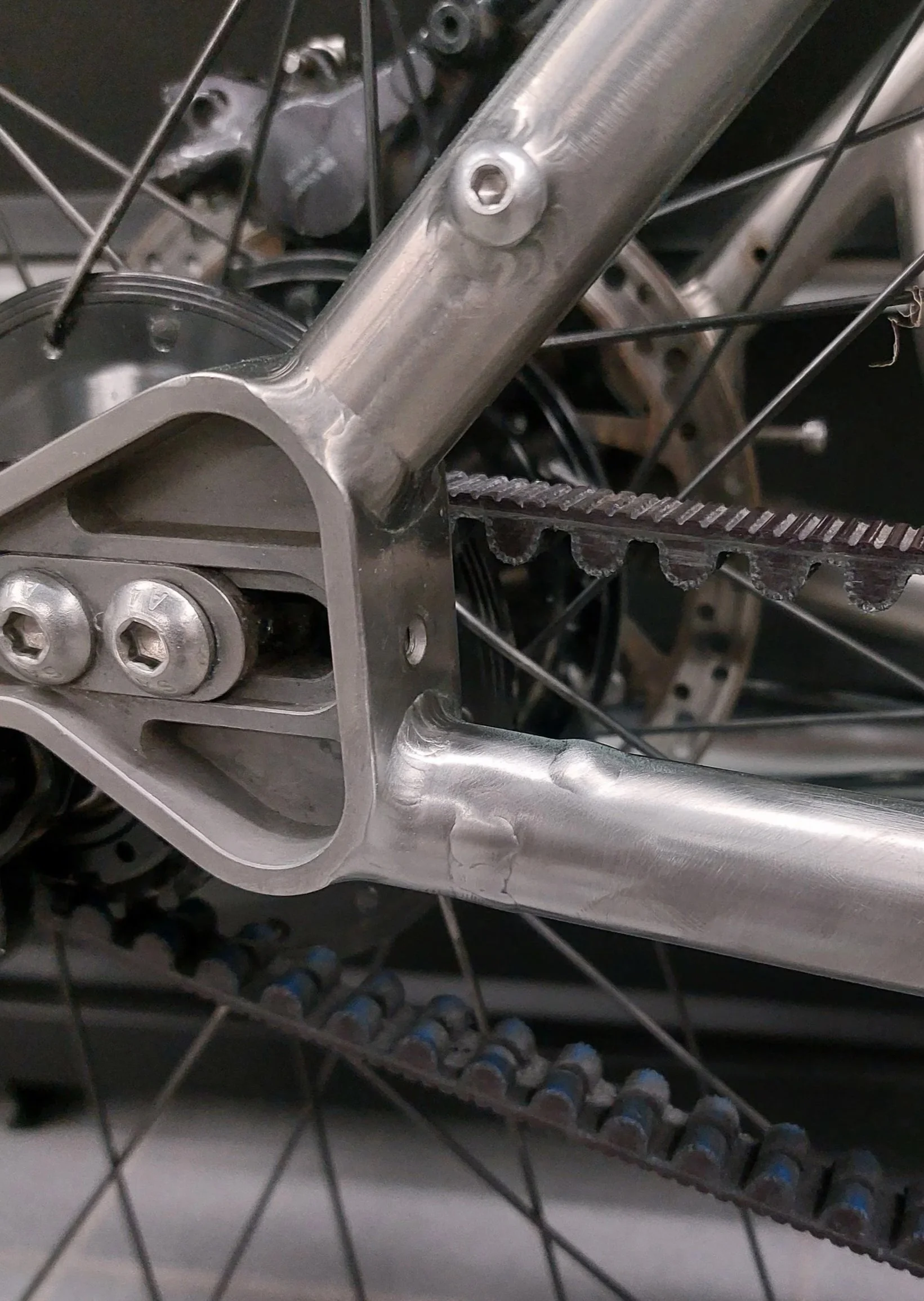

Quick fix of almost completely cracked chainstay of a titanium mountainbike.

Quick fix of cracked toptube of a classic Kona titanium mountainbike

Turning down road cassettes for mtb hubs